design and construction of an autoclave|diagram of an autoclave : retailer Pressure oxidation (POX) • Installation Qualification (IQ) – Ensuring equipment is installed as per manufacturer’s specification • Operation Qualification (OQ) – Ensuring equipment, critical .

{plog:ftitle_list}

Several tools developed by Parker Autoclave Engineers are presented to help accomplish proper valve, fitting and tubing installation and maintenance. Video tutorials are available on our websiteAutoclave Engineers Low Pressure Fittings are designed for use with low pressure valves and tubing. These fittings feature improved SpeedBite compression connections with larger orifices for excellent flow capabilities.

how does a autoclave work

An autoclave was designed and constructed to sterilize materials/items used in such healthcare institutions. The autoclave has a liquid capacity of 2 litres and is heated electrically with a.

diagram of autoclave with label

© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .1) to design the autoclave based on codes and project rules; 2) to analyze the manufacturing costs. As a starting point for this project is the need of IST for acquiring an autoclave.

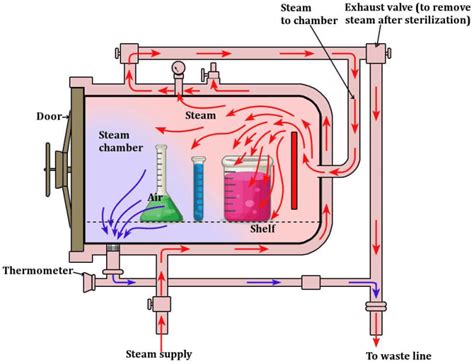

Pressure oxidation (POX) An autoclave is a machine that provides a physical method of sterilization by killing bacteria, viruses, and even spores present in the material put inside of the vessel using steam under pressure. Autoclave sterilizes the materials by heating them up to a particular temperature for a specific period of time. The autoclave is also called a .Construction •a. Pressure Chamber . Autoclaves are important devices to ensure the sterilization of materials containing water as they cannot be sterilized by dry heat sterilization. Besides, autoclaves are used for various other purposes. 1.They are used to decontaminate specific biological waste and sterilize media,

Design and construction of autoclaves must coordinate the specific properties of each material used to provide reliable long-term operation. Download conference paper PDF Similar content being viewed by others

An autoclave was designed and constructed to sterilize materials items used in such healthcare institutions to control pathogenic organisms and has a liquid capacity of 200 liters. One of the major problems confronting healthcare professionals is the control of pathogenic organisms. This is because microorganisms are present in our environment and may .An autoclave designed and constructed to sterilize materials/items used in healthcare institutions showed a decrease in the growth of microorganisms at high temperature with a high exposure time.

diagram of an autoclave

autoclave simple diagram

how to make refractometer calibration fluid

There are vari ous types of autoclaves, such as-industrial autocla ve, medical aut oclave, laboratory autoclave, etc. All o f these auto claves are batch operating t ype wh ich has one and only .

Having such autoclave will be beneficial for the industry to reuse the material through processing and have good fresh material. Design Stress at design temperature (247℃) by interpolation; 250℃ 247℃ 462000 × 2.5 4 × 0.045 = 64.25 𝑀𝑝𝑎 Therefore, design stress > Hoop & Axial stress The Design stress is Safe.

US Autoclave is a world leader in autoclave design and construction. Beyond autoclave construction, US Autoclave is committed to supporting the needs of daily operations. Service, replacement parts, technical support, autoclave refurbishing, controller updates, and cart systems are primary examples of services offered by US Autoclave. .Design and construction of an autoclave: Authors: Oyawale, F. A.||Olaoye, A. E. Issue Date: Nov-2007: Publisher: Akamai University, Hilo, Hawaii: Abstract: One of the major problems confronting healthcare professionals is the control of pathogenic organisms. This is because microorganisms are present in our environment and may contaminate .

Explanation of autoclave manufacturing process, from design to production. Autoclave manufacturing involves several key steps: Design: Engineers create detailed blueprints considering size, materials, and safety. Material Procurement: High-quality materials like stainless steel are sourced for construction.@inproceedings{Oyawale2007DesignAC, title={Design and construction of an autoclave}, author={Festus Adekunle Oyawale and A. E. Olaoye}, year={2007} } F. Oyawale, A. Olaoye; Published 1 November 2007; Medicine; One of the major problems confronting healthcare professionals is the control of pathogenic organisms. This is because microorganisms .

An autoclave was designed and constructed to sterilize materials/items used in such healthcare institutions. The autoclave has a liquid capacity of 2 litres and is heated electrically with a 2kw . Factors Affecting Autoclave Size. In a recent paper on design of autoclaves for pressure leaching of nickel laterites (King, 1996), the following have been listed as the determining factors in the pressure autoclave size: solids throughput and size distribution; selected autoclave circuit; slurry density; retention time; temperature; number of . AbstractDue to its various advantages, autoclaved aerated concrete (AAC) has been gaining popularity in masonry construction in recent years, and consequently, numerous studies have been conducted in this area since the mid-1980s. Unfortunately, research .

The objective of this research is to design and construct a maintenance-free autoclave that requires little skill to operate and can be readily available for general sterilization purposes. LITERATURE REVIEW The first autoclave was “Chamberland’s Autoclave”. Charles Chamberland, a colleague of Pasteur, built upon Denis Papin’s work.An autoclave designed and constructed to sterilize materials/items used in healthcare institutions showed a decrease in the growth of microorganisms at high temperature with a high exposure time.Autoclave Design Considerations Most composite manufacturing personnel are familiar with autoclave processing and understand basic autoclave operating principles. The autoclave is considered the most “robust” of all composite processing options. It is tolerant of both mistakes by lay-up technicians and material problems.

14.3 Safety valves – design and construction 10 14.4 Door interlocking safety devices 10 14.5 Safety devices to protect the operator when unloading the autoclave 11 Table 1 — Thermal door lock temperature settings 12 14.6 Double door autoclaves 12 14.7 .PDF | On Mar 31, 2015, Amila Wickramasinghe published Comprehensive Design Project Individual Autoclave Design | Find, read and cite all the research you need on ResearchGateThe autoclave will design and constructed from locally available materials to make the cost of purchase . “Design and Construction of an Autoclave”. Pacific Journal of Science and Technology. 8(2):224-230. [2]. European Union. “European Standard BS EN 554:1994. Sterilisation of Medical Devices - Validation and Routine Control of

An autoclave designed and constructed to sterilize materials/items used in healthcare institutions showed a decrease in the growth of microorganisms at high temperature with a high exposure time.

Aspects that will need to be addressed in a viable commercial system include: energy required for pumping, the embodied energy required for construction, the embodied energy in fertilizer, and the .

The design and construction of autoclaves are critical to their performance and safety. The BS 2646-1:2021 standard provides detailed guidelines on the materials, construction techniques, and design features that are essential for creating reliable and efficient autoclaves. These guidelines ensure that autoclaves are built to withstand the . The BSL-3 autopsy laboratory design uses the principles of concentric ring containment and access control. 13,79 The concentric ring construction puts the area of highest biosafety need (BSL-3 isolation autopsy) at the core of the laboratory, surrounded by zones of decreasing biosafety (BSL-3 general autopsy followed by BSL-2 support laboratory .

Appendix A—Proposed design provisions, p. 524.3R-61 Appendix B—Commentary on proposed design provisions, p. 523.4R-67 Appendix C—Design examples, p. 523.4R-72 Example 1: Design of an AAC floor panel Example 2: Design of an AAC shear wall Example 3: Design of an AAC diaphragm Example 4: Design of load-bearing vertical wall panel FOREWORD After reviewing the comments and experiences of the laboratory people for the design and construction of the autoclave, a general layout is designed using SolidWorks software, with the details of connections and screws added. With the help of Abaqus software, the supplementary design is completely analyzed.

autoclave machine diagram

autoclave for high temperature corrosion

$629.99

design and construction of an autoclave|diagram of an autoclave